Professional illustration about Synonyms

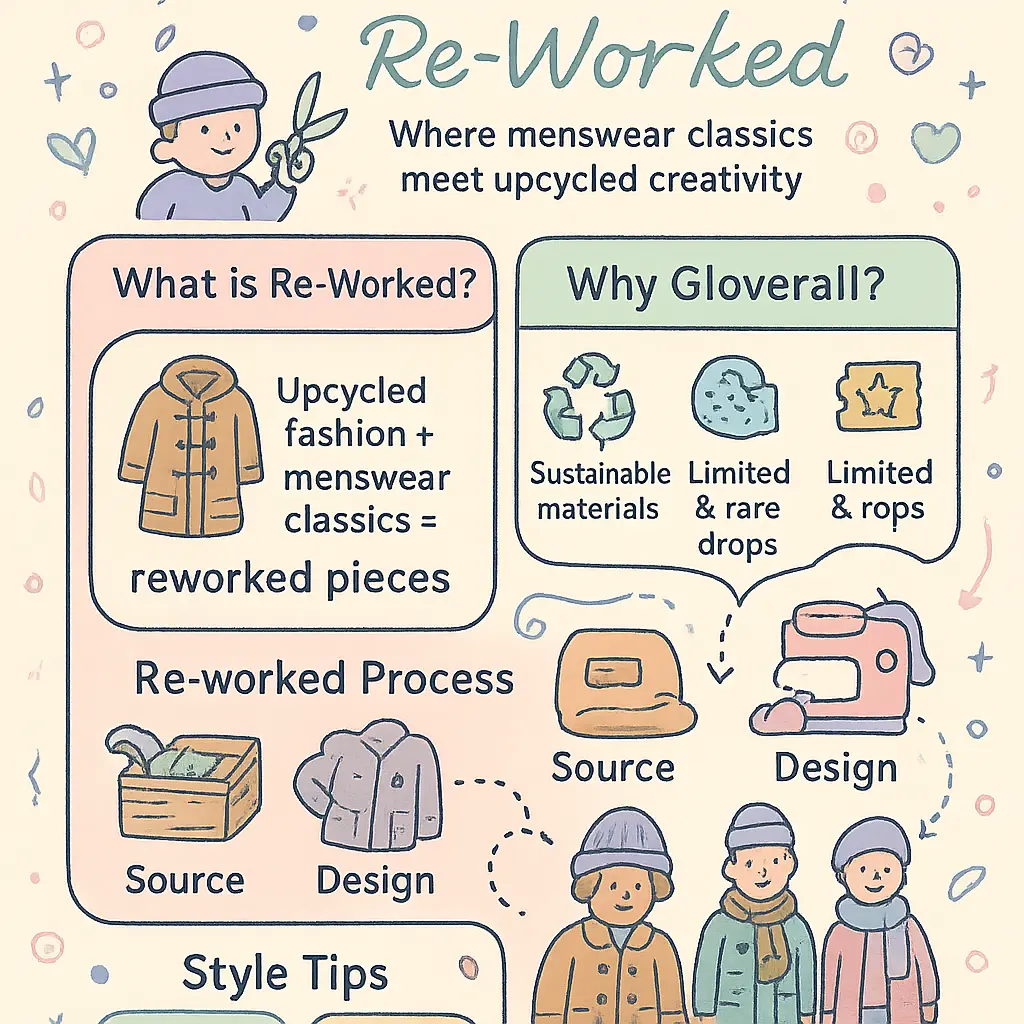

What Is Re-Worked?

At its core, “re-worked” describes a growing movement in menswear and vintage workwear where garments, especially classics like Carhartt jackets, shirts, vests, and utility pants, are meticulously transformed from their original forms into unique, contemporary pieces. This is not just a trend—it’s a philosophy rooted in sustainable fashion, upcycled fashion, and slow fashion principles. Think of it as the intersection where heritage clothing meets responsible production, with an emphasis on quality craftsmanship, circular design, and the creative use of repurposed materials.

The process behind reworked clothing often starts with sourcing deadstock cloth, archived textiles from old textile mills, or authentic vintage items that have stood the test of time—pieces that might otherwise end up as resale clothing or, worse, in landfills. Skilled independent designers and small workshops, like those behind Blok Knives, Gloverall, or Statedwoods Co., breathe new life into these garments. They might patch up a pair of utility pants using deadstock selvedge denim, add contemporary details to a classic Carhartt chore jacket, or combine different patterns and fabrics to create a one-of-a-kind vest. Each project is a testament to the art of workwear repair, prioritizing durability and premium menswear aesthetics.

Reworking isn’t just about aesthetic updates; it’s about function and longevity as well. In an age where denim recycling initiatives such as Blue Jeans Go Green and Cotton Incorporated are gaining momentum, reworked clothing supports a circular fashion economy. By extending the lifespan of heritage pieces—whether it’s a Gloverall duffle coat or a pair of sturdy utility pants—these practices reduce waste, conserve resources, and champion responsible consumerism. The commitment to small batch production ensures each item retains a sense of exclusivity and craftsmanship that mass-produced fashion simply cannot offer.

UK fashion boutiques like The Hambledon and forward-thinking retailers such as Canopy are showcasing how reworked menswear captures the spirit of both nostalgia and innovation. Their curated collections often feature jackets and shirts with visible mending, patchwork, and creative repairs—signs that these pieces have stories to tell. Unlike fast fashion, reworked workwear is built to last, emphasizing durable gear and product care. This approach appeals to modern men who value authenticity, individuality, and the legacy of classic workwear brands while consciously supporting more sustainable shopping habits.

For those new to reworked fashion, exploring these pieces is a chance to discover the difference that comes with thoughtful design, heritage fabrics, and true craftsmanship. Whether you’re hunting for a vest made from deadstock military cloth, a unique pair of utility pants with reimagined details, or a jacket crafted from repurposed denim, the re-worked category offers a distinctive alternative to off-the-rack menswear. It’s an investment in both style and substance, reflecting a commitment to circular initiatives, independent design, and the enduring appeal of well-made clothing.

Professional illustration about Carhartt

Key Benefits in 2026

When it comes to reworked menswear in 2026, the key benefits extend far beyond aesthetics or trend appeal—they touch every aspect of sustainability, craftsmanship, and personal style. First, responsible production is front and center: brands like Carhartt and independent designers such as Statedwoods Co. and Blok Knives have doubled down on small batch production, ensuring every piece—be it jackets, utility pants, or heritage clothing—doesn’t just look good, but also minimizes waste. Thanks to innovations in circular design and upcycled fashion, vintage workwear and deadstock cloth are being repurposed into premium menswear, creating one-of-a-kind items with real character.

Durability and quality craftsmanship stand out in 2026 as foundational benefits. Reworked workwear, such as the iconic Carhartt jackets and Gloverall vests, are not just repaired but enhanced—reinforced seams, upgraded textiles from renowned UK textile mills, and meticulous detailing ensure gear that’s built to last. This is especially crucial for consumers who value workwear repair and product care, turning classic items into future-proof investments. Resale clothing and archived cloth offer new life to older menswear, giving shoppers access to rare, high-quality pieces that would otherwise be lost to time.

Sustainable fashion initiatives are thriving, with collaborations like Blue Jeans Go Green and Cotton Incorporated fueling denim recycling and circular initiatives. These programs empower brands and buyers alike to participate in the lifecycle of their garments, from collection to repurposing, reducing landfill waste and conserving resources. By choosing reworked clothing, men in 2026 support a more ethical supply chain, as transparent sourcing from heritage mills and careful repurposing of materials foster trust and accountability.

Versatility and individuality are also major draws. Menswear enthusiasts can experiment with unique silhouettes—think utility pants with vintage patches, statement vests crafted from deadstock cloth, or shirts reimagined with archived textiles from past seasons. Canopy and The Hambledon, two standout names in UK fashion, have pioneered collections that combine heritage pieces with contemporary flair, allowing men to express their style while supporting slow fashion. This approach nurtures a wardrobe that is both distinctive and adaptable, perfect for anyone looking to move beyond mass-produced looks.

Economic value is another significant benefit. While premium reworked menswear often carries a higher upfront cost, the longevity and timeless appeal of these pieces offer better value in the long run. Investing in durable gear from reputable brands or independent designers means fewer replacements and less money spent over time. Moreover, resale clothing markets have grown, allowing consumers to recoup investment or explore new styles without waste.

Practical tips for maximizing these benefits in 2026 include: - Prioritizing brands known for responsible production and quality craftsmanship, such as Carhartt, Gloverall, and independent designers. - Seeking out pieces made from deadstock cloth or archived textiles for exclusivity and sustainability. - Participating in circular initiatives like denim recycling programs to extend the life of your wardrobe. - Learning basic workwear repair techniques to keep heritage clothing in peak condition. - Embracing slow fashion by curating a wardrobe of versatile, reworked menswear staples (utility pants, vests, jackets, shirts) rather than fast fashion trends.

Ultimately, the shift toward reworked and upcycled menswear in 2026 isn’t just about following the latest UK fashion movement—it’s about making smarter choices for your personal style, your wallet, and the planet. By embracing repurposed materials, supporting circular design, and investing in quality craftsmanship, men are building wardrobes that honor both tradition and innovation, all while championing sustainable fashion for the years to come.

Professional illustration about Reworked

Latest Trends in Re-Work

One of the most exciting developments in 2026’s menswear landscape is the explosive growth of reworked and upcycled fashion, especially in heritage clothing and vintage workwear. Brands like Carhartt continue to lead by example, introducing limited-edition reworked jackets, shirts, vests, and utility pants crafted from deadstock cloth sourced from historic textile mills. These pieces aren’t just about nostalgia—they’re about pushing responsible production practices and sustainable fashion to the forefront of the industry. For instance, collaborations between Carhartt and independent designers like Statedwoods Co. and Blok Knives are bringing small batch production and circular design into mainstream menswear, highlighting quality craftsmanship and durability.

This reworking trend isn't confined to a single style or segment. The Blue Jeans Go Green initiative by Cotton Incorporated remains a game-changer, funneling post-consumer denim into new resale clothing opportunities and even home insulation, championing denim recycling and the circular fashion movement. Meanwhile, premium menswear shops such as The Hambledon in the UK are curating collections of reworked workwear and heritage pieces, blending classic utility with modern tailoring. These shops are increasingly favoring archived cloth and deadstock textiles over newly manufactured fabric, reducing waste and bringing exclusive character to each item.

Independent designers and small ateliers like Canopy and Gloverall are also reimagining vintage workwear, using repurposed materials to create one-of-a-kind garments. The focus on product care—from repair guides for workwear to customization services—reflects a shift toward slow fashion and long-term ownership. Instead of buying new, consumers now seek out reworked jackets, vests, and shirts with visible mending, patchwork, and creative reimagining. Utility pants and sturdy vests get second lives with reinforced panels, hand-stitched details, and updated fits, appealing both to traditionalists and modern streetwear enthusiasts.

Resale clothing platforms have also adapted, featuring special collections of reworked workwear that showcase UK fashion’s global influence. These platforms provide detailed provenance, highlighting the heritage of each item and the responsible production methods behind it. The demand for durable gear made from repurposed materials is spurring textile mills in the US and Europe to innovate with new processes for circular initiatives, making it easier for designers to source sustainable raw materials.

For guys looking to make smarter choices in 2026, scouting for reworked menswear means focusing on a few key tips: - Check fabric provenance: Seek jackets, shirts, and utility pants made with deadstock cloth or responsibly sourced repurposed materials. - Prioritize craftsmanship: Look for visible mending, hand-finished details, and small batch production labels—a sign of quality and sustainability. - Support independent designers: Smaller brands frequently offer more transparency, innovative circular design, and unique limited-edition pieces. - Learn product care: Embrace the responsible mindset by investing in workwear repair kits and learning basic patchwork, extending the life of your favorite heritage clothing. - Verify circular initiatives: Opt for brands involved in denim recycling, cotton upcycling, and resale clothing programs that prove their commitment to sustainable fashion.

The latest trends in re-worked menswear showcase a dynamic intersection of style, sustainability, and responsible consumerism. Whether you're after a rugged Carhartt vest reimagined from archived cloth or a limited-edition Gloverall jacket made in collaboration with a local artist, the message in 2026 is clear: reworked fashion isn't just a passing trend—it's redefining the future of UK fashion and global menswear.

Professional illustration about Workwear

Re-Worked vs. Original

When you’re weighing the appeal of re-worked pieces against their original counterparts, there’s so much more at stake than just aesthetic preferences. Reworked clothing—especially in menswear categories such as Jackets, Shirts, Vests, Utility Pants, and classic Vintage Workwear—represents a shift toward sustainable fashion, responsible production, and individuality. A perfect example comes from Carhartt, whose heritage clothing is often reimagined by independent designers and UK fashion labels like The Hambledon, Blok Knives, and Statedwoods Co. These creators breathe new life into archived cloth and deadstock materials, transforming what might have been landfill fodder into modern, functional pieces. By contrast, the originals—whether they’re iconic Carhartt utility jackets or Gloverall’s classic duffle coats—embody the timeless, rugged utility that built their legacy, but may lack the unique contemporary edge or environmental benefit of upcycled fashion.

Comparing Design and Functionality

The true dividing line between re-worked and original lies in design intent and craftsmanship. Reworked workwear often features unique patchwork, visible mending, and unexpected textile combinations. For instance, a pair of utility pants reconstructed using deadstock cloth sourced from historic textile mills might feature premium denim recycling from circular initiatives like Blue Jeans Go Green or Cotton Incorporated. This practice not only enhances durability but also highlights quality craftsmanship, echoing the slow fashion movement’s emphasis on longevity and product care. Meanwhile, original pieces hold a certain purity—untouched lines, classic fits, and standardized materials. While appealing for collectors and purists, originals typically lack the story-rich details and inventive construction that set re-worked menswear apart.

Sustainability and Circular Design

From an eco-conscious perspective, going re-worked signals a commitment to circular design and upcycled fashion. Brands and designers employing small batch production techniques are not only preserving heritage pieces but also pushing forward sustainable fashion. By repurposing materials from vintage shirts or compromised jackets, they extend the life cycle of each garment and drastically cut down on waste. This kind of responsible production is increasingly valued in 2026, as consumers become more aware of the fashion industry’s impact on the environment. For example, projects like Canopy and resale clothing platforms promote the reuse and repair of workwear, celebrating the rugged beauty of patched denim and reimagined vests. In contrast, buying new, original pieces—while supporting legacy brands—may contribute to ongoing resource consumption unless the brand has adopted their own circular initiatives or uses responsibly-sourced fabrics.

Style and Personal Expression

Another major difference lies in the realm of personal style. Re-worked clothing offers a one-of-a-kind aesthetic. You might find a shirt patched with deadstock textile from a mid-century mill or a vest featuring mixed materials curated by an independent designer. These pieces become wearable stories, reflecting the wearer’s appreciation for unique design, heritage, and sustainability. For men seeking premium menswear that truly stands out and tells a tale, re-worked garments can be the ultimate form of self-expression. On the other hand, supporters of originals gravitate toward authenticity and legacy—preferring pristine, unaltered versions that pay homage to the brand’s archival craftsmanship.

Practical Advice for Buyers

If you’re considering which route to take for your wardrobe, it’s worth analyzing intended use, maintenance, and longevity:

Opt for re-worked items if you value unique style, sustainable fashion, and pieces with a story. Look for durable gear built from repurposed materials and upcycled fashion elements. Choose originals when you need standardized fits, authentic heritage clothing, and guaranteed brand quality. Ensure product care practices match the rugged finish, especially for pieces like Carhartt jackets or Gloverall coats. For items like utility pants and workwear repair, consider brands involved in denim recycling or circular design—these signals a commitment to both quality and environmental responsibility.

Balancing the virtues of re-worked versus original comes down to what you value most: the narrative and creativity layered into reworked menswear, or the trusted durability and archival purity of originals. In 2026, both categories hold their place in the modern wardrobe—just for very different reasons.

Professional illustration about Menswear

How Re-Working Works

At its core, re-working means transforming existing garments—whether they’re authentic Carhartt jackets, deadstock utility pants, or vintage workwear shirts—into fresh, uniquely styled pieces. The process starts by sourcing these foundation pieces, often sought out by independent designers and small batch producers focused on responsible production and sustainable fashion. For example, brands like Gloverall and Canopy target UK fashion’s heritage clothing archives, hunting for premium menswear items such as blue jeans, vests, and resale clothing treasures that carry stories in every seam.

Step-by-Step: From Sourcing to Creation

- Curation & Sourcing: Designers carefully select vintage or deadstock cloth, prioritizing items with sturdy textiles—think Carhartt double-knee utility pants or cotton workwear from renowned textile mills. These pieces are chosen not just for their durability but their repair potential and their iconic style that resonates with menswear enthusiasts.

- Assessment & Planning: Each garment is inspected for quality craftsmanship and signs of wear. Rather than discarding worn spots, reworked clothing embraces them, using visible mending or contrasting patches to add character—often seen in upcycled fashion projects and denim recycling efforts led by initiatives like Cotton Incorporated and Blue Jeans Go Green.

- Design & Re-Cutting: Repurposed materials are carefully re-cut, sometimes combining different garments into hybrid items—imagine a workwear vest crafted from archived cloth or a Gloverall jacket enhanced with deadstock pocket details. Circular design thinking guides every choice, favoring reversible features, modular closures, and repair-friendly seams for slow fashion.

- Assembly & Finishing: Skilled makers apply techniques that blend traditional workwear repair methods with modern aesthetics. Brands like Blok Knives and Statedwoods Co. illustrate how premium menswear can bridge practical durability with artisanal flair, producing durable gear perfect for both urban and outdoor needs.

Customization for a Unique Edge

Custom re-worked pieces often feature hand-stitched patches, screen printed logos, and creative upcycling—turning old textile mill remnants into statement garments. Some designers experiment with mixing utility pants and vests from different eras, or add functional upgrades like reinforced elbows, tool pockets, and adjustable hems. The result is heritage pieces with renewed life, tailored for today’s wearers seeking both style and responsible production.

Circular Initiatives and Care Advice

One standout aspect of modern re-working is its commitment to circular initiatives. Brands partner with denim recycling programs and push for circular design to keep materials in circulation longer, reducing fashion’s environmental footprint. Product care is emphasized—guides on cleaning reworked workwear or repairing premium menswear ensure garments remain wearable for years. The Hambledon, a UK fashion outpost, educates buyers about preserving the quality craftsmanship of reworked jackets and shirts, fostering a culture of repair over replacement.

Practical Tips for Re-Worked Enthusiasts

- When shopping for re-worked pieces, always check for authenticity and the quality of archived cloth.

- Ask about the reworking techniques used, especially if you’re interested in items from small batch producers or independent designers.

- Embrace visible mending and modular upgrades—they add individual character and support circular fashion.

- Follow product care instructions from sellers to maximize the longevity of your reworked garment.

Understanding how re-working works not only empowers you to make more responsible fashion choices but invites you to appreciate the craft behind upcycled fashion and repurposed materials—a perfect marriage of heritage clothing, modern style, and sustainable values driving menswear innovation in 2026.

Professional illustration about Jackets

Industries Using Re-Worked

When looking at industries leveraging reworked principles in 2026, it’s clear that the concept has evolved far beyond simple upcycling. Today, a variety of sectors are making use of reworked clothing, deadstock cloth, and repurposed materials as integral elements of their business strategies. The fashion and textile industry remains at the forefront, driven by rising consumer demand for sustainable fashion and responsible production practices, but the impact extends into design, retail, and heritage manufacturing.

In the premium menswear space, notable brands are redefining classics. Take Carhartt, whose durable utility pants, jackets, and shirts are often reimagined by independent designers and small labels. These reworked workwear pieces utilize archived, deadstock cloth sourced from legacy textile mills, offering fresh perspectives on vintage silhouettes. Such collaborations have gained traction in the UK fashion scene, where shops like The Hambledon curate exclusive collections combining heritage clothing from Carhartt, Gloverall’s traditional duffle coats, and specialized items from Statedwoods Co. or Blok Knives, a British brand famous for incorporating upcycled wood and metal into their craft. These examples illustrate how quality craftsmanship and small batch production are used to create truly unique products, giving vintage workwear a new lease on life.

Denim recycling initiatives mark another notable industry effort. Programs like Blue Jeans Go Green, led by Cotton Incorporated, have set a benchmark in circular design by converting old denim fabrics into insulation and new products. This appeals directly to consumers now prioritizing sustainable choices—especially in North America, where reworked and upcycled denim remains prominent in both mainstream and independent labels. These circular initiatives have influenced the broader resale clothing market, fueling the demand for archived cloth and heritage pieces that can be reconstructed or restored.

In the world of utility and outdoor gear, durability and adaptability are key. Companies like Canopy and boutique menswear makers focus on reworking vintage jackets, shirts, and vests to maximize longevity. Methods such as expert workwear repair, textile upgrades, and reinforced stitching respond to the growing interest in slow fashion. These brands utilize repurposed materials and focus on product care, giving each item a distinct history and utility while reducing waste from fast fashion cycles.

Retailers have embraced resale and reworked items, not just for their sustainability credentials but also for their unique style. Secondhand shops and curated boutiques actively source pieces with durable gear lineage—such as utility pants or classic Carhartt jackets—and commission independent designers to upcycle them. In 2026, collaborations between shops like The Hambledon and makers such as Blok Knives and Statedwoods Co. create limited-edition runs and one-off reworked products, benefiting from both the appeal of authenticity and the strong market appetite for exclusive, narrative-rich fashion.

Even within the broader design industry, reclaimed and reworked materials have seen a resurgence. Furniture companies reimagine repurposed materials from textile mills or vintage clothing, integrating deadstock cloth and aged leather into limited-release collections. This approach not only promotes environmental responsibility but also leverages heritage aesthetics, resulting in pieces that tell a story—a trend especially prevalent in high-end design and boutique retail environments.

For businesses wanting to get involved, several strategies unlock the potential of reworked goods. Prioritize sourcing genuine deadstock and archived cloth, engage in small batch production with independent designers, and educate customers about garment maintenance and repair. By focusing on quality craftsmanship and authentic heritage, brands can meet rising demand for sustainable, premium items while distinguishing themselves in a crowded market.

Across all these sectors, one thing’s clear: the industries using reworked and upcycled fashion are setting new standards for durability, storytelling, and sustainability in 2026. Whether through denim recycling, heritage workwear reconstruction, or creative use of repurposed textiles, the reworked movement is driving a future where circular design and responsible production are more than trends—they’re becoming business essentials.

Professional illustration about Shirts

Top Re-Working Techniques

When it comes to reworked clothing in 2026, the top re-working techniques blend traditional craft with modern innovation, catering to consumers who prize sustainable fashion, quality craftsmanship, and unique style. At the heart of premium menswear and vintage workwear brands like Carhartt and Gloverall, these techniques revive classic pieces—think utility pants, jackets, shirts, and vests—by transforming deadstock cloth and archived fabrics sourced from historic textile mills into standout, refreshed garments.

Deconstruction and Upcycling:

One of the most sought-after methods sees designers physically deconstructing items such as Carhartt jackets or Gloverall coats to add entirely new elements—whether patchwork panels from deadstock denim or custom pockets made from surplus utility pants. Independent designers like Blok Knives and Statedwoods Co. bring fresh energy by integrating unexpected textiles or hardware salvaged from vintage workwear, infusing their creations with a narrative and premium finish. By practicing small batch production, they minimize waste and support responsible manufacturing.

Paneling and Patchwork:

Reworked clothing frequently features paneling—strategically placed contrasting fabrics and patchwork in heavyweight twill, duck canvas, or recycled denim. Projects like Blue Jeans Go Green, supported by Cotton Incorporated, champion denim recycling, contributing panels and trims from reclaimed jeans. These intricately patched jackets, shirts, and vests are not only durable but also carry the story of responsibly sourced materials. Fashion houses and resale platforms in the UK like The Hambledon and Canopy are especially known for embracing circular initiatives that highlight these details in their heritage clothing offerings.

Overdyeing, Distressing, and Custom Washes:

American menswear labels lead with proprietary washes, overdyeing, and hand-applied distress treatments to maintain a cohesive aesthetic across reworked workwear. Overdyeing deadstock cloth is particularly popular for revitalizing faded colors, while controlled distressing techniques give utility pants and vests an authentic, lived-in quality coveted by slow fashion enthusiasts. Brands invest in product care instructions to ensure these heritage pieces last for years, turning new buyers into repeat customers.

Repurposing Functional Elements:

High-quality repairs, visible mending, and creative reconfiguring of functional details like snap closures, utility pockets, or reinforced elbows have become a hallmark of durable gear. Artisans at Canopy and Blok Knives, for example, adapt original closures from deadstock jackets, swap in heavy-duty zippers sourced from UK textile mills, and embroider signature patches—all efforts anchoring the garment in authenticity while meeting modern utility needs.

Hybridization and Resale Integration:

Another technique gaining traction involves hybridizing pieces from different eras and brands—think Gloverall duffles repurposed with Carhartt duck cloth sleeves, or vests fashioned from UK military surplus blended with American workwear details. Through circular design, independent designers like The Hambledon rework resale clothing into exclusive menswear drops, tracing provenance and optimizing archived cloth for a second (or third) life.

Archival Restoration and Storytelling:

Restoring archival heritage clothing isn’t just about repair—it’s about storytelling. Skilled craftspersons document the journey of reworked pieces, using repurposed materials and traditional techniques learned from generations working in textile mills. Embroidered labels or stamped tags share the garment’s timeline, turning every reworked vintage item into a one-of-a-kind collectible for fashion-forward consumers.

If you’re considering reworking your own menswear, look for pieces with natural fibers like cotton or wool. Opt for responsible production—consider partnering with local tailors focused on slow fashion or joining workshops on workwear repair. Keep an eye on heritage brands and independent designers who prioritize quality over quantity and offer product care tips to extend the life of your reworked clothing. By embracing these innovative techniques in 2026, you’ll not only invest in unique, durable pieces but also contribute to a more sustainable, circular fashion future.

Professional illustration about Vests

Quality Control Methods

Ensuring top-tier quality control is essential for brands and independent designers delving into reworked menswear—especially those focused on heritage clothing, vintage workwear, and sustainable fashion. In 2026, quality standards have evolved alongside responsible production and circular design initiatives. Brands like Carhartt, Gloverall, and Blok Knives, as well as boutiques like The Hambledon and Statedwoods Co., exemplify thoughtful quality stewardship through multi-stage inspection and care.

Key quality control methods start at the sourcing phase. Whether it’s repurposed deadstock cloth from leading textile mills or authentic archived cloth acquired from resale clothing platforms, provenance and material integrity are meticulously recorded. For premium reworked pieces, such as utility pants or jackets using Blue Jeans Go Green recycled denim, fibers are tested for durability, colorfastness, and chemical residue to guarantee garment safety and longevity. Cotton Incorporated and similar organizations provide updated testing standards for 2026, ensuring recycled fibers meet premium performance benchmarks.

During small batch production, craftspersons employ enhanced inspection processes:

- Visual assessment: Each vintage workwear piece—be it a Carhartt vest or a heritage utility shirt—is closely inspected for visible flaws, incorrect labeling, and traceability.

- Physical wear simulation: Men’s jackets or shirts undergo abrasion and stress tests to ensure they withstand real-world wear and washing cycles.

- Fabric touch and panel comparison: Material hand-feel is checked against both heritage originals and modern batch specifications, preventing mismatches when combining various repurposed materials. Small workshops like Canopy and Blok Knives often bring in outside inspectors or collaborate with textile labs for third-party approval.

Repair and reinvention are the heart of reworked clothing, so workwear repair expertise is critical. Seam integrity, reinforced stitching, and hardware testing (zippers, buttons, rivets) ensure each item’s durability. For instance, when upcycling classic Carhartt menswear into new utility pants or vests, skilled technicians reinforce stress points using contemporary slow fashion standards.

Documentation and traceability protocols in 2026 utilize QR-embedded labels detailing each item’s repair, modification, and previous lifecycle—vital for both resale and upcycled fashion transparency. Tools such as Gloverall’s digital heritage archive allow buyers to track the jacket’s provenance and follow recommended product care guidelines.

End-of-line checks before release to boutiques like The Hambledon or Statedwoods Co. feature several advanced steps:

- Batch sampling and variance testing: Random picks from production lots are destructively tested to expose hidden faults, further guaranteeing consistent quality.

- Eco-certification alignment: For brands participating in denim recycling or circular initiatives (like Blue Jeans Go Green), audit trails are kept to comply with strict sustainable fashion certifications.

Practical advice for up-and-coming menswear designers in the UK fashion scene: Partner with textile labs for fiber analysis, work with independent auditors for batch sampling, and implement consistent product care communication—your customer’s confidence relies on wearable, beautiful, and responsibly reworked pieces. Ultimately, the success of reworked menswear in 2026 rests on combining quality craftsmanship, innovative inspection, and heritage-informed diligence. Ensuring each jacket, shirt, vest, or pair of utility pants tells its story—while standing up to everyday life—cements both your reputation and the future of premium upcycled fashion.

Professional illustration about Utility

Sustainability and Re-Work

In 2026, sustainability has become a non-negotiable in menswear, and the movement toward re-worked vintage workwear is at the center of this evolution. Brands like Carhartt—infamous for durable gear—and revered independent designers are breathing new life into heritage clothing by producing reworked jackets, shirts, utility pants, vests, and accessories that blend upcycled fashion with modern sensibilities. Rather than contributing to the wasteful cycle of fast fashion, these labels employ practices like small batch production, circular design, and comprehensive workwear repair to extend product lifespan and minimize environmental impact.

One of the most innovative approaches is the use of deadstock cloth from historic textile mills for limited-edition menswear. For example, Carhartt has partnered with UK fashion tastemakers like The Hambledon and Statedwoods Co. to repurpose archived cloth into utility pants and unique vests, ensuring no material goes to waste. These pieces offer real added value to consumers who care about responsible production—and proudly sport items with traceable, meaningful origins.

The upcycled trend in workwear repair is supported by organizations such as Blue Jeans Go Green and Cotton Incorporated, which facilitate denim recycling programs across the US. This helps brands and resellers collect unwanted jeans, transform them via innovative textile recycling methods, and revive them into new blazers or utility pants with premium craftsmanship and durability. Such circular initiatives not only reduce landfill waste but also create a culture where quality denim repair is routine—reinforcing a slow fashion mindset.

Menswear connoisseurs, meanwhile, are snatching up reworked shirts, jackets, and vests crafted from vintage fabrics and deadstock materials sourced in limited quantities. Gloverall—an iconic name in heritage pieces—collabs with independent designers globally, producing reworked outerwear and statement vests that celebrate tradition while serving modern utility. Similarly, Blok Knives and Canopy have reworked vintage utility pants into rugged yet refined premium menswear sought after by collectors.

A key benefit of reworked clothing is the capacity for custom product care. Instead of treating garments as disposable, more brands encourage users to practice repair and maintenance: patching tears, resewing seams, and repurposing fabrics for new uses. The entire lifecycle of the garment revolves around durability and mindful consumption—advice not just for brands, but for every buyer aiming for a greener closet.

It's not just about nostalgia for heritage or vintage—it's about embedding craftsmanship and responsible sourcing into every facet of modern fashion. For instance, resale clothing platforms now spotlight limited runs of high-quality reworked jackets and utility pants, offering detailed info about the original mills, batch sizes, and designers’ philosophies. The appeal is both environmental and personal: you’re investing in gear that tells a story, supports independent creatives, and helps drive the adoption of circular initiatives.

As we move well into 2026, circular design is more essential than ever. Instead of designing with waste in mind, progressive brands source repurposed materials—from denim scraps to archived cloth—and create versatile, durable menswear in small quantities. The process underscores the value of premium craftsmanship, and signals a shift away from fleeting fads toward investment in timeless styles. Staunch advocates—whether UK innovators like The Hambledon or American trailblazers—continue to redefine sustainability in menswear by spotlighting responsible production and heritage clothing as desirable, practical, and inherently stylish choices.

Professional illustration about Deadstock

Re-Worked Product Examples

When it comes to re-worked product examples in modern menswear, few sectors are buzzing quite like reworked vintage workwear and contemporary upcycled fashion. Brands and independent designers from both the US and UK fashion scenes are actively driving these trends, redefining what it means to invest in quality, character-rich heritage clothing in 2026.

Take, for instance, American staples like Carhartt. Once famed for their rugged, utilitarian gear, Carhartt jackets, shirts, vests, and utility pants are now the raw material for a wave of reworked clothing specialists. Through processes such as patching, overdying, and strategic repairs, artisans transform deadstock cloth and archived garments into premium menswear-chic. This upcycled take with Carhartt pieces keeps the spirit of workwear alive but introduces bold, new aesthetics—a far cry from mass-market fast fashion of the past.

The holistic approach to denim recycling has also greatly evolved. Companies involved in programs like Blue Jeans Go Green, now supported by leaders such as Cotton Incorporated, repurpose mass-collected denim into both new vintage-inspired apparel and eco-responsible insulation. Original blue jeans from defunct textile mills are upcycled, repaired, or remixed into fresh silhouettes like chore coats or relaxed utility trousers, accentuating both slow fashion value and responsible production.

Across the pond, the UK offers an abundance of creative energy. Famed for championing reworked and circular design, British labels and makers inject innovation into durable gear by restoring resale clothing and giving heritage pieces new twists. Gloverall, known for classic duffle coats, started offering small-batch capsule runs where vintage jackets are dismantled and reconstructed using repurposed materials, nodding to both history and contemporary utility. The Hambledon, a mainstay in UK menswear retail, spotlights independent designers—like Statedwoods Co. and Blok Knives—who favor reusing surplus deadstock cloth for limited-run shirts and artistic apron vests, each piece unique in details and fabrication.

A key principle in all these re-worked product examples is premium craftsmanship and care—a true breakaway from throw-away culture. Brands place focus on product care tutorials, encouraging buyers to maintain and repair their acquisitions for max longevity. Canopy and other modern boutiques have even partnered with on-site tailors, so new and secondhand buyers alike can experience personalized workwear repair, alteration, and rejuvenation services. The result is an emphasis on sustainability without sacrificing quality.

How do you spot a genuinely re-worked piece? First, look for evidence of circular initiatives: brands transparently stating their use of upcycled, deadstock, or repurposed textiles; care instructions tailored to hybrid or unique constructs; and batch-level product stories—perhaps noting rescuing salvage fabrics from closure at historic textile mills, or upcycling damaged but beautiful niche vests that were otherwise headed for landfill.

Product diversity is also skyrocketing. Nowadays you’ll find utility pants spliced from two-toned denim, jackets bearing the marks of beautifully hand-stitched repairs, and shirts patched with contrasting archived cloth fragments—each telling a tale of both past labor and present innovation. Reworked clothing doesn't only dominate streetwear aesthetics; it flows comfortably into more refined knitwear, outerwear, and accessories, with young creatives blending tech and tradition.

Buying from those who specialize in reworked workwear or upcycled fashion is more than a style move in 2026—it is a type of activism. Consumers are ensuring that premium, durable gear stays in circulation, reducing the environmental burden one garment at a time. Plus, by favoring pieces with real-story heritage and quality craftsmanship, today’s informed buyers guarantee themselves long-lasting, responsibly made, and resolutely individual wardrobe staples. The ever-growing array of menswear, jackets, shirts, and vests forged from the bones of textile history is proof positive that circular design and quality truly coexist when reworking vintage.

Professional illustration about Textile

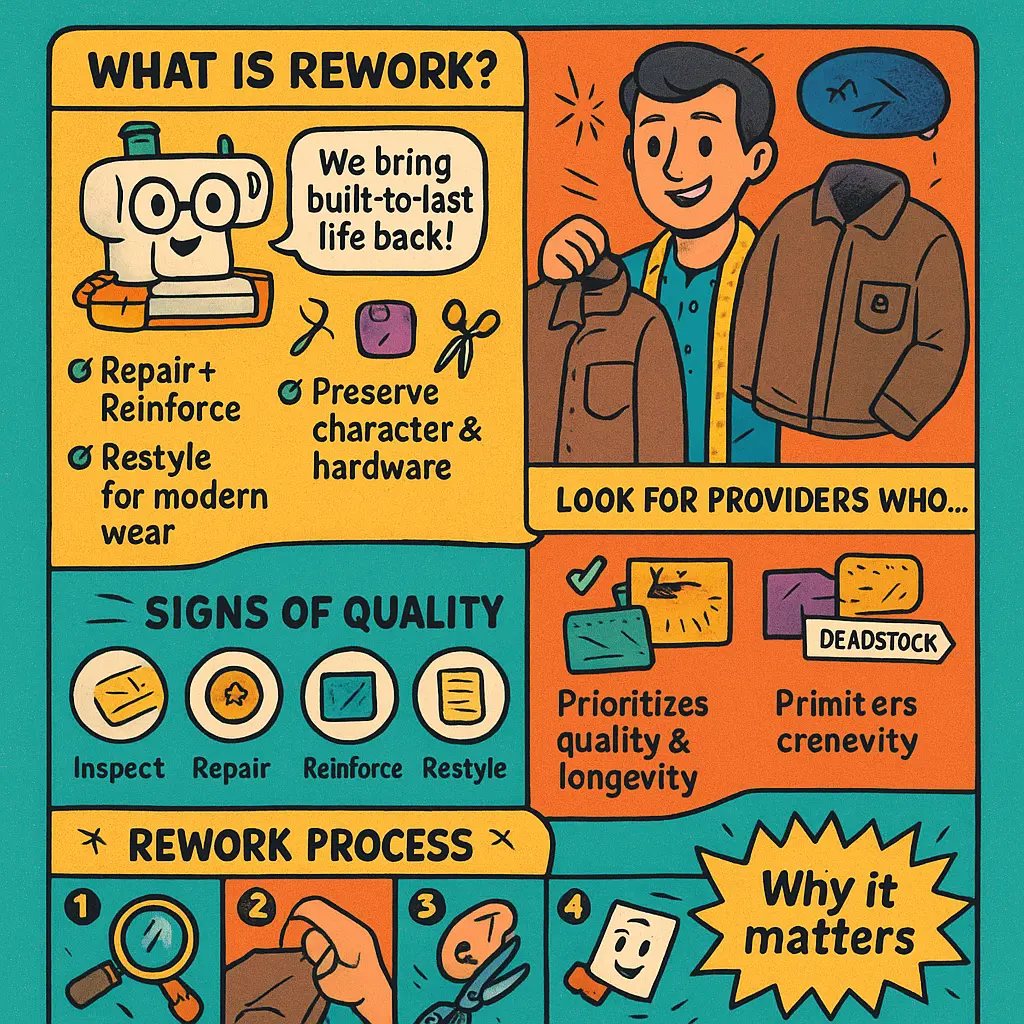

Choosing a Re-Worked Service

As you’re considering a re-worked service for upgrading your wardrobe, it’s essential to pinpoint providers with expertise in breathing built-to-last life back into heritage clothing, like Carhartt jackets or deadstock cloth from renowned textile mills. The best reworked services prioritize quality craftsmanship and responsible production processes, often specializing in vintage workwear repairs, utility pants restoration, and menswear upgrades. It pays to inspect their commitment to sustainable fashion — do they engage in circular initiatives such as denim recycling, upcycling premium UK fashion brand items, or small batch production using archived cloth from labels like Gloverall or work with independent designers such as Blok Knives and Statedwoods Co.?

Look for clues indicating authenticity and value: Does the provider have transparent documentation detailing the origin of materials, whether those blue jeans were sourced from Blue Jeans Go Green or cotton supplied through Cotton Incorporated programs? Are repairs done by skilled hands, specializing in slow fashion, reworked menswear favorites like tailored shirts, durable vests, and responsibly sourced resale clothing? Investigate how they repurpose materials—some use deadstock textiles from renowned mills, others incorporate elements from heritage pieces, focusing on utility and classic details that make vintage workwear appealing in the first place.

When picking a re-worked service, consider the personalization options and attention given to product care. Many specialist workshops in the reworked clothing space operate in small batches, emphasizing significance in every piece. For example, The Hambledon, a highly regarded UK menswear curator, chose to champion circular design in their 2026 collection by integrating repurposed utility pants and jackets, refreshed with deadstock cloth. Likewise, a company like Canopy stands out for treating vintage Garhartt shirts and jackets to thorough workwear repair processes, ensuring garments maintain character while adding durability for daily use.

A thoughtful analysis of customer reviews and before-after photos can reveal whether a service gives proper respect to the heritage value of the items returned to market as premium menswear. Buyers should also ask services about care guidelines, rework history, and maintenance to extend the lifecycle of reworked workwear pieces. If denim rejuvenation is the main purpose — say, restoring vintage selvage jeans into ultra-durable gear — confirm that the service correlates to circular denim recycling standards in 2026 and uses authentic textile techniques, not fast-fashion shortcuts.

Furthermore, since many reworked clothing providers work with limited stock, inquire about unique menswear item findings—archived utility pants, vests upcycled with historical details, or jackets boasting a mix of classic British tailoring and modern American styling. This blend of practical know-how, vintage archive access, and focus on material provenance is what separates top reworked clothing experts from mass resellers. Whether you seek standout statement shirts pieced together with repurposed fabrics or workwear repair that preserves sentimental value, choose a re-worked service invested in transparent sourcing, product rejuvenation, and ongoing care. This approach ensures that your wardrobe embraces the durability and authenticity of responsible, future-facing fashion, with every item retaining a story worth passing on.

Professional illustration about Heritage

Cost Comparison 2026

When considering the cost comparison for reworked menswear and vintage workwear in 2026, shoppers are faced with dynamic choices across price points and value drivers. Classic Carhartt Reworked Jackets, for example, stand out in the upcycled fashion market with their thoughtful restoration and unique archived cloth. In the current retail landscape, an authentic, responsibly produced reworked Carhartt jacket now typically costs between $150 to $400, reflecting slow fashion, single artist labor, and premium menswear finishing. Compare this to mainstream mass-market alternatives: off-the-rack utility jackets from major UK fashion outlets can start as low as $60-$120, albeit with disposable construction and little longevity. The true cost value favors reworked clothing for consumers seeking durable gear and lasting style.

Vintage workwear, especially deadstock items from historic textile mills—amber equivalents from Gloverall duffel coats or genuine Blok Knives artisanal studio outerwear—now command prices ranging from $200 to well above $600, depending on sourcing scarcity, heritage appeal, and textile type. The price is partly driven by limited runs and small batch production. No two reworked Garments are truly identical; detailed repairs, workwear restoration, and high-quality craftsmanship mean such pieces not only support sustainable practices, but lend a collector's appeal. These pieces frequently appreciate in resale clothing markets, often retaining or increasing value even as minimal signs of wear compile extra authenticity.

In the utility segment, reworked pants constructed from repurposed materials, such as denim offcuts routed through initiatives like Blue Jeans Go Green by Cotton Incorporated, are shaping pricing conversations. A pair of so-called "recycled workwear trousers" might retail at $110 to $250, factoring in post-consumer denim recycling, circular initiatives, and substantial labor investment. Standard mass-produced jeans, contrastingly, still base at just $28-$75, but with fast fashion drawbacks—compromised fit and subpar textile resilience.

Shirts, vests, and innerwear designs from curated UK fashion sources like The Hambledon or innovative makers such as Statedwoods Co. offer further cost distinctions. Reworked cotton shirts, employing locally archived cloth and repairing methods, are more likely priced between $65 and $150 per item. This is indicative of the greater emphasis on product care, ensuring extendable lifespans and authentic heritage piece status. Meanwhile, machine-exported basics remain less, near the mass-market threshold—but generally lack the upcycled character that slow fashion enthusiasts now prioritize in 2026.

Of course, certain independent designers—notably those active in circular design and responsible production—find that higher base costs are related to transparent supply chains and genuine small batch quality. While consumers pay upfront (sometimes ×3 over mass-commercial alternatives), expert analysis shows they benefit through actual wear-months, with reworked workwear pieces being regularly repairable, causing delayed replacement cycles. Experts estimate, for example, an original deadstock vest from a small-run textile house lasting ten times longer than high street vests, given proper product care.

Material and provenance are the twin pillars for today's pricing. Garments built from deadstock cloth sourced from closing textile mills—utilized in Gloverall coats and even Canopy overalls—motivate investment but simultaneously help foster responsible production and slow down landfill accumulation. When factoring in repair costs, convenient exchange opportunity in resale clothing communities, and inherent style longevity, enthusiast consumers calculate lower lifetime cost for these heritage clothing classics compared to rapid run items.

For those deciding if circular initiatives and sustainable fashion premium merits a higher silent price sticker in 2026, the evidence compels: upfront investment balances out in greater durability, continuation of archived aesthetics, and socially conscious shopping. Whether you thumb through premium reworked jackets, utility pants made through denim recycling, uniquely restored shirts, or single-origin vests from niche textile mills and expert-designed heritage collections, your ultimate decision ties to measured value—not just initial price, but total aesthetic, lifespan, and intangible reputation benefits as the landscape evolves.

Professional illustration about Jeans

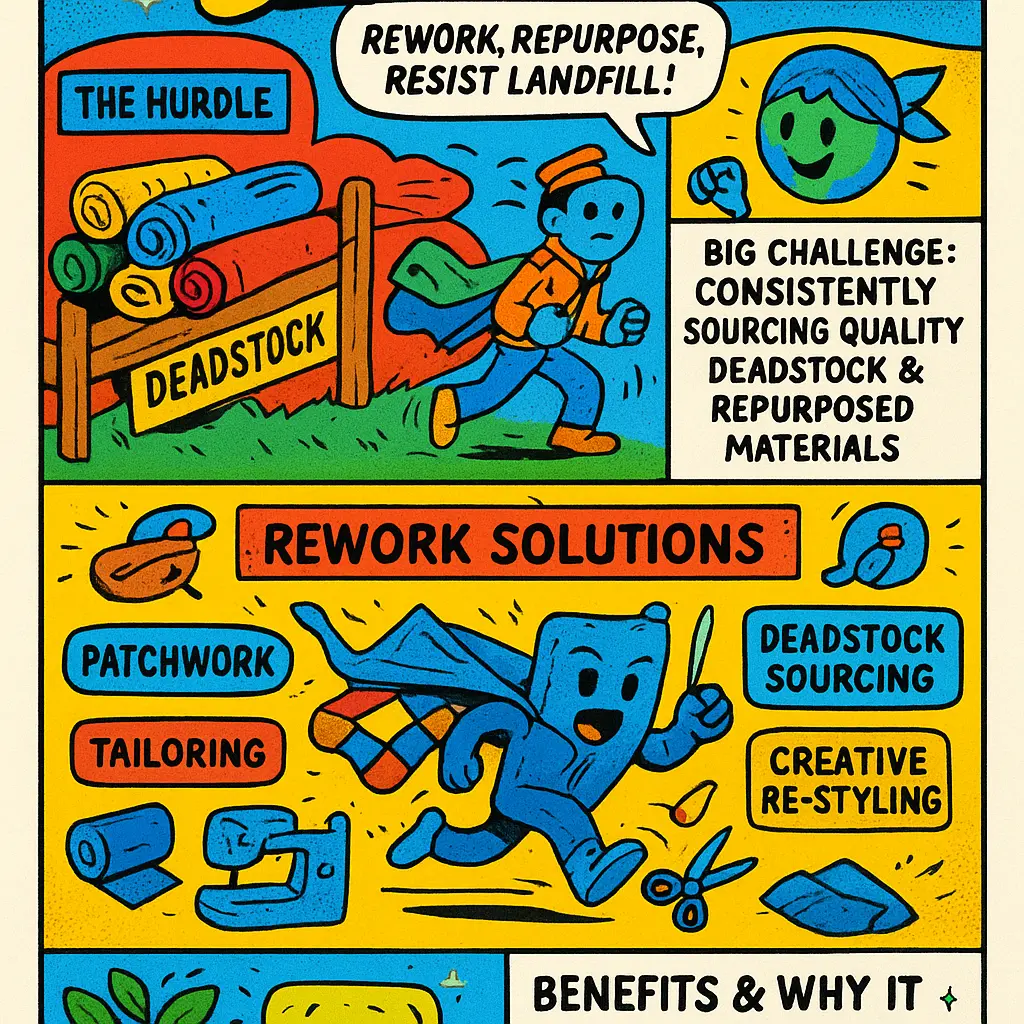

Common Challenges

One of the most frequent hurdles in the world of reworked vintage workwear and premium menswear lies in consistently sourcing quality deadstock cloth and repurposed materials. While names like Carhartt, Gloverall, and even smaller independent designers such as Blok Knives or Statedwoods Co. have made headlines in 2026 for their bold circular fashion moves, even established labels report pressure points. Most US and UK textile mills now specialize in small batch production or modernized dying techniques, giving rise to supply bottlenecks. It’s especially tough to track enough authentic utility pants, work jackets, or vests boasting durable gear qualities—true workwear libraries dwindled decades ago. As upcycled fashion, with blue denim at the vanguard and broader initiatives (like Cotton Incorporated’s modern version of Blue Jeans Go Green) gain traction, artisan-makers constantly find themselves in a race, competing to access most-wanted old-stock items or archived cloth.

Reworking is more than seam-ripping and replacement—it inherently tests a maker’s skills in product care, material familiarity, and color matching. Menswear clashing between faded vintage workwear and current fashion ideals roots fresh complications; resizing garments or reconstructing vests using a blend of rescued Korean, US, and Japanese overshirts can quickly bloat costs and drive up workshop time-per-piece dramatically. Ensuring fabric durability—for instance, restoring thirty-year-old jackets from The Hambledon–UK Fashion’s premier heritage retailer—might mean advanced patching, meticulously executed lining, or synthetic thread support in friction-required spots. Future customers now expect quality craftsmanship, requiring full transparency of production story and visible care for responsible production values nurtured by these circular efforts.

Ongoing vocabulary confusion may trip up even engaged consumers: vintage, reworked, resale clothing, remade—each term lands slightly differently. For instance, Synonyms—some brands even use the term in their names—crowd out authentic upcycled-hard-goods within the SEO sphere, driving genuinely repurposed men’s fashion under a sea of neighboring key terms. Navigating clear language (i.e., reworked workwear, not simple resale) becomes vital for communicating value to sustainability-minded shoppers. This extends to collaboration; multi-brand mini-capsules between Gloverall, Canopy League collaborations, and creative upcycling at Statedwoods Co., hinge on open origin and process disclosure. Otherwise, well-intentioned pieces risk appearing like craft projects rather than sought-after heritage clothing, diminishing buyer confidence in the slow fashion movement as a whole.

Fit is another core challenge within the market for reworked menswear and vintage jackets or shirts. Overemic production generations ago means heritage pieces most available today skew too boxy or irregular for a modern silhouette—mirroring industrial 20th-century function now uncoupled from daily casualwear needs. Independent designers must walk the line: maintain the tough, practical spirit while making utility pants and vests actually wearable for new owners and broader resale clothing markets. Size tagging and return compatibility introduce friction, especially for one-off items where crafting to safari, chore, or trucker jacket standards might require deep tailoring know-how few workshops can now affordably offer in volumes.

Finally, circular design dovetails with the rise in prospective customer interest but also spawns market hurdles—can these operations meet ethical, transparent guidelines through the whole chain? Documenting recycled denim sources, charting the miles a jacket has traveled, demonstrating metrics on upcycled fabric ratios—the onus is on independent producers, mainstream labels, and even archival experts like The Hambledon to reinforce claims about durability and provenance at every point. Responsible production extends beyond product patterns; surviving and thriving through tiny batch release means championing best-case accounting procedures, wash house selection and addressing real concern over waste disposal—all alongside stellar product photography and rights-respecting educational campaigns.

Despite substantial market growth by early 2026 in reworked workwear, brand trust issues and logistic supply chain limits often determine whether innovative projects reach either core enthusiasts or mainstream style spaces. Effective product storytelling for these complex, responsibly produced utilitarian goods—crafted from truly archived cloth with genuine blue jeans recycling success—is the ongoing secret edge, separating fast passing fashion fads from bona fide heritage design names carrying rerouted clothing far into the future.

Professional illustration about Incorporated

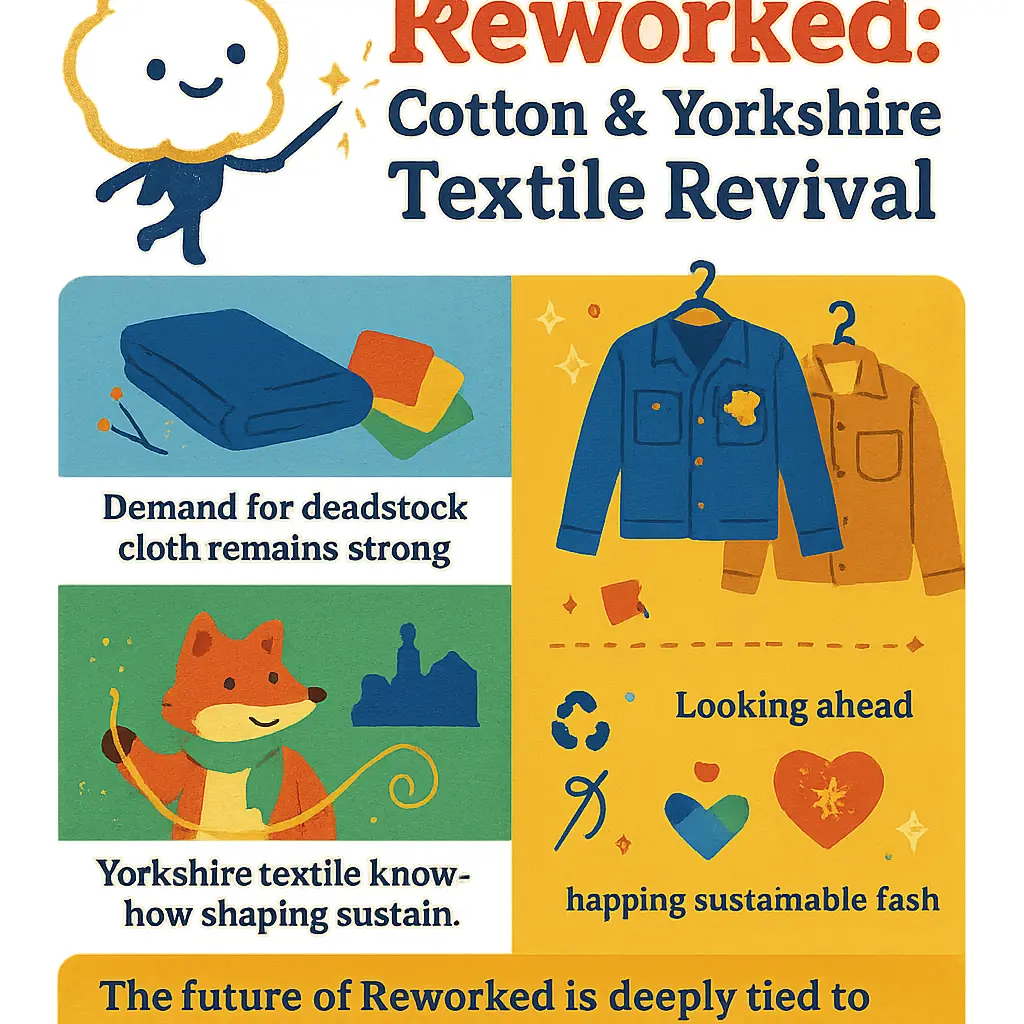

Future of Re-Worked

Looking ahead, the future of Reworked is deeply tied to the surge in sustainable fashion and how Yorkshire’s textile know–how reimagines legendary staples for a new era. While demand for deadstock cloth and heritage workwear like Carhartt utility pants and premium denim jackets remains strong, the 2026 landscape shows a distinct pivot driven by circular design and upcycling initiatives. Industry movers like Gloverall, Canopy, and Statedwoods Co. are actively demonstrating how archived cloth and durable natural fibers can be transformed into small batch collections or totally reengineered by independent designers. For instance, Blok Knives collaborates regularly with menswear innovators and vintage collectors, leveraging salvage-vintage patches and workwear repair tactics to invent distinctive cropped shirt–microvest hybrids and mod x jackets—expanding the synonyms of reworked clothing far beyond the typical repurposed camo or rugged Carhartts vibe. Industry-backed heritage clothing initiatives such as Blue Jeans Go Green, sponsored by Cotton Incorporated, also enable reworked creators to directly upcycle post-consumer denim into new field-ready builds rather than sending tons to landfill.

Engagement between Reworked artisans and new UK fashion retailers—including cultivation through the regional tastemakers at The Hambledon or specialized e-collector markets—is intensifying. As consumers revise their wardrobes with mindful intent, attention spans for fast fashion dwindle and in its place, closely tracked emerges appreciation for unique vintage edits, especially when transparency about production and the repairability of garments is clearly prioritized. Recent runs like utility mesh vests with unpublished mill remnants or company-branded overshirts appropriating 60s military deadstock pick up massive buzz during small batch drops, making rarity factor and responsible production central value propositions. Independent designers thrive by doubling down on archive ancestry and superior workwear visual language—from select American oil-stained painter’s canvas to robust chainstitched denim likely cut in-joint with Japanese textile mills.

In step with advancing tools for product care, elements like modular panelling, double-reinforced torque points, and ready-to-wash instructions widen the lifespan of each Reworked piece. Local ateliers routinely offer denim recycling clinics and upcycled fashion workshops, showing how workwear vest linings can merge kickstart nostalgia around Y2K core Aesthetic with today’s expectation for lasting, fixable clothing. Meanwhile, the mainstreaming of authenticated resale clothing has benefitted veteran crafters who rely on modern digital marketplaces to offload reimagined one-off Gloverall parkas or Carhartt painter x chore coats directly to ethically minded buyers. The reworked rulebook embraces more color, stitching specials, and contrasting layered aesthetics than ever before—a far stretch from mid-10s redundancy—and 2026 Menswear pays extra for innovative takes using off-books materials like tech-natural fiber hybrids. Resale channels foster more intimate recycling loops, interactive trade-ins, and highlight festival staple throwbacks re-spun from real textile mill edge pieces.

For collectors and new converts, tracing the provenance of woven tags to cotton-based upcycler partnerships assures authenticity and tells a versatile story within the finale garment. It ushers appreciators to prioritize less clichéd merit—superior quality craftsmanship, credible small-label baxter collaborations, artillery-repair shop case studies—over mere collegiate nostalgia or anonymous resale scores. Rather than aimless mass retreading, leading UK parlance now spots Re–Worked as modeled by method: true material archiving, matchless stitch appeal, and brand-proven utility ultimately harmonize both the ethos of heritage pieces and the responsibilities accompanying modern circular workwear rotation. As the requisites for genuine premium menswear align further towards traceability and physically persistent, low-footprint gear, the pathway for Reworked—Messrs. and Mses. of the vintage industrial, sustainably-forward mindset—stands broader yet more rigorous. Slow fashion principles, utility-driven aggression, and an ever-refreshed creative license will engineer what is next, so look for reworked workwear that offers unrepeatable detail—a byproduct of cultural roots and absolute product resilience for decades beyond 2026.

Professional illustration about Gloverall

FAQs About Re-Worked

For those just getting familiar with reworked fashion and wondering how it blends sustainable trends like upcycled fashion with menswear classics, below you’ll find answers to the most frequently asked questions about Re-Worked. Whether you’re after rare Carhartt jackets, curious about archived deadstock cloth from local Textile Mills, nervous about product care, or intrigued by collabs with influential players across the UK like Gloverall, Blok Knives, or cult boutiques such as The Hambledon—these insights will help shape your understanding if you’re chasing true repurposed workwear or looking to invest smartly in durable gear for 2026 and beyond.

What Does “Re-Worked” Actually Mean in 2026?

The term re-worked, much more than just a collective synonym for modification or upcycling, now describes carefully deconstructed or repaired pieces—especially in vintage workwear. Think of classic Carhartt or heritage pieces painstakingly rejuvenated: panels mended, shapes re-imagined for comfort or utility value, or old vests refashioned through circular techniques and quality craftsmanship. So, when you see “reworked” worn proudly in independent menswear shops across the UK, it signals real, responsible production. Renowned makers have embraced slow fashion more actively than ever; recycled cotton, unused deadstock cloth rescued from textile mills, and denim (as seen by disruptions like Cotton Incorporated’s Blue Jeans Go Green initiative), are front and center right now.

Is the Quality Comparable to Brand-New Gear, or Is It a Risk?

Today's reworked clothing—especially the compact runs favored by designers—often offers durability that rivals new off-the-peg pieces. Small batch production allows for rigorous sourcing—not just any leftover denim goes into utility pants, the archived cloth has tracked origins for transparency, and repairs to jackets or vests regularly resort to heritage archival sewing, yielding truly premium menswear. Producers way up the value chain foster collaborations (e.g., experienced clothing repair companies partnered with big players like Carhartt) so quality matches or exceeds original deadstock output. People choosing slow fashion especially like quality over the instant newness buzz routinely offered in mass retail of previous years. And don't miss performance aspects—riveted pockets get refitted for current device sizes, workwear shirt joints get triple stitched, so often Re-Worked outlast many historical first-issue pieces now dated by gentle fast fashion cycles.

How to Identify Legit Reworked Pieces (and Avoid Regular Resale)?

Spot authentic reworked workwear by hunting for visible prepurchase tweaks: note a uniquely reshaped hem, a modern reinterpretation on vintage outdoor jackets via added utility pockets, smart FEATURE NAVY in Ben Davis fabric scales (not sold in most basic resale shops). Especially in 2026, product descriptions contrast “resale clothing” with federated details—batch tags and heritage signatures of repair stitched straight onto offcloth, original materials annotated bilingually, plus sourcing details of featured indie designer finishing teams (for instance, Statedwoods Co introducing added blend fibers with animated storycards about the restoration quantum of each part). Don’t be confused: if listing features workwear repair specs, mark it DNA Re-Worked, not simple secondhand.

If searching US-made heritage clothing, also request info about archived mill output—Gloverall sweaters, for example, crafted out of old textile mill deadstock as part of conventional local circular initiatives or the fiercely rare 40-year factory-find utility pant panels. Sellers embracing circular design list which traditions or innovations the piece honors, making each reworked garment an informed purchase. Meanwhile, still check sizing changes; reworked menswear (unlike box-standard shirts) biases cut for bodies and task—fitting is evolutive, not OEM-straight.

Is Reworking Always Sustainable Compared to New Investment?

Bluntly, not every "repurposed material project" saves more water, hukes or CO2 from the get-go—sometimes late-stage adjustments even add processes, but in good responsibly-crafted examples (or brand collabs, say, with Canopy or pathway-certified Circular Producer channels) a vast natural resource reduction shapes the offer. Statistics in spring 2026 show carbon savings workfully double-digit whenever cotton denim is taken into in-house micro-bleaching and denim recycling for bluecollar jeans issuances from Blue Jeans Go Green bak sztk producer affiliates, proving why demand soars. Choose retailers and brands that display location/circular initiative progress badges—you’re helping slow global wastage by strategic wallet shifts toward this trend. Sales staff LelBlur at The Hambledon, for example, run you through eras/clients conscious separation: completely repurposed materials, expired but lovingly refreshed batch pieces, limited Gloverall "mill archives stitch-ins”—you learn exactly how responsibly (UK Fashion leading the European spice of it).

Tips for Caring for Your Re-Worked Gear

Since piece integrity not only springs from the initial custom refurbishment but also from your maintenance efforts: favor mild, color-fast washes; use non-biological cleaning routine (especially for riveted patches, wool-edging ventures, and dying preservation care in menswear textile stories); always check origin designer notes post-purchase. Some retailers offer added annual care guidelines in Circular Bags or opt-in in-box informational cycles. None of this is optional if you want your jacket’s next resurrection in 2042—it worked for the pieces already back from archive death in 2022.

Here's a pro process: dry utility pants flat occasionally on racks (takes less heat); glove-damp areas prone to fade/patch transmission CSSed fix for best repair reward. If lost care tags, dial up maker contact—they’ll instruct you if to mat, air, or tumble based on precise cloth batch, a personal connection rep.'s now standard.

Why Are Re-Worked Pieces Popping Up in Every Premium Boutique Jersey?

In just two years, brands and sellers have recognized not only the soulful value innate to reworked vintage but that wearable struggles are prized on every urban avenue from Soho to Smithfield. Rapid expansion fed fierce seeking cities—even independent designer workshops stream indie-fitted batch pieces guaranteed repairs almost “subscription-like.” Preferred actors run glue unions as local base, like Blok Knives refabricating gear for kitchen utility use out of end-run reclaimed pants fabric—every repurposing event layered now beneath strong resale two-way narratives beside bigger circular fashion conservation arms. That evolution ensuring utility-based repair, reimagined deadstock choice is iconic: globetrotting shopping agents rate local finds beside big-chain releases, certifying older shapes with the verve urban sampler guys expect.

If you want satisfaction deeper than “buy-and-trash,” swap, cycle, restore: this is the evolved premium menswear journey, with every living step documented somewhere—the products hum with artistry above regular fast “made new sale.”

Ultimately, Re-Worked clothing stands for innovation bound to heritage, quality as experience told on fabric, and cultivating demand for pieces that built the hands that wore them before—powerful stuff continuing lead the intriguing curve in sustainable-industrial blend for 2026’s global style squads.*